Why Precision Is Important in Medical CNC Machining

When it comes to medical devices and components, precision isn’t just a nice-to-have—it’s mission critical. From surgical instruments to implantable components, every part must be manufactured to exact specifications to ensure safety, reliability, and compliance. That’s where CNC machining comes in—and why companies across the medical industry trust Modelcraft Co. to get it right.

The Stakes Are High in Medical Manufacturing

Unlike consumer or commercial products, medical parts often go inside the human body or are used in high-stakes surgical environments. There’s no room for error. A micrometer too small or too large could affect how a part fits, functions, or holds up under stress. That’s why tight tolerances, clean finishes, and exacting quality control are absolutely essential.

How CNC Machining Delivers Unmatched Accuracy

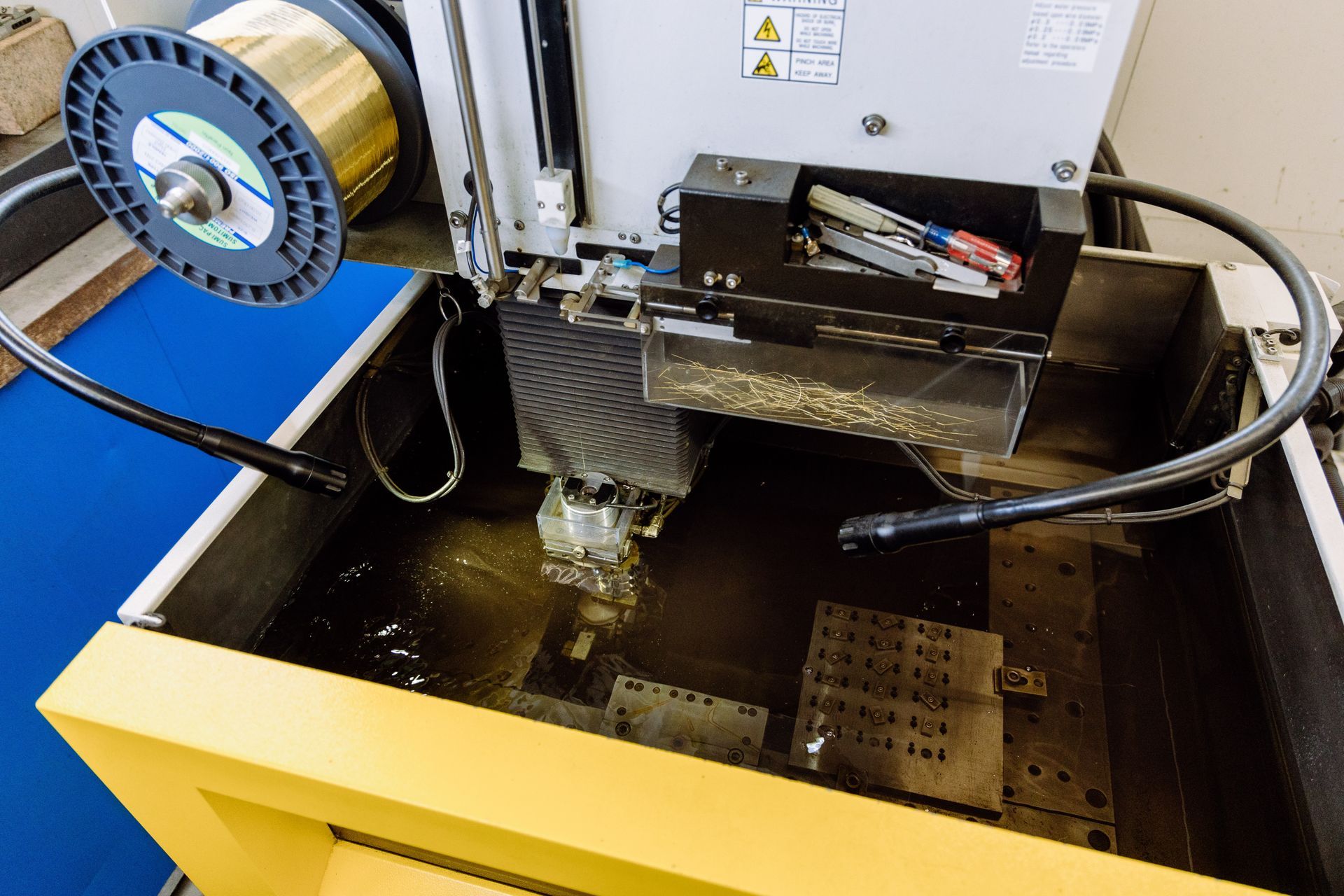

With CNC machining, computer-guided tools execute ultra-precise movements based on CAD/CAM files, making it possible to hit those tight tolerances consistently. At Modelcraft Co., we specialize in small, high-precision components and use advanced equipment like wire EDM, milling, turning, and grinding to produce complex geometries out of materials like stainless steel, titanium, and high-performance plastics—all common in the medical field.

Quality Is Built Into Our Process

We don’t just machine parts—we inspect, document, and verify every step of the way. Modelcraft Co. is both AS9100D and ISO 9001:2015 certified, meaning our quality systems meet the highest international standards. Our team is trained to catch what others might miss, ensuring every part we deliver meets the demanding requirements of the medical industry.

Enabling Better Patient Outcomes

Precision in medical CNC machining isn’t about the part—it’s about the person who relies on it. Every implant, housing, or surgical tool we manufacture plays a role in helping someone heal, recover, or thrive. And that’s why we take our work seriously.

Because In Surgery, “Close Enough” Isn’t Close Enough

If you need a machining partner who understands the critical nature of medical components, you’re in the right place. Modelcraft Co. combines nearly 60 years of expertise with state-of-the-art technology to deliver parts that perform when it matters most. Get in touch with Modelcraft Co. to talk about your next project—we’re here to help you make it flawless.

Recent Articles