How Modelcraft Co. Tackles Unique Manufacturing Needs

In today’s competitive manufacturing landscape, companies need more than just precision machining—they need a partner who can solve complex challenges with innovative solutions. Modelcraft Co. has spent nearly 60 years tackling unique manufacturing needs, helping customers in the medical, aerospace, and commercial industries achieve their goals with precision, efficiency, and reliability.

From handling tight tolerances to working with advanced materials, our team thrives on challenges. Here’s how we approach unique manufacturing requirements and deliver high-quality, turnkey solutions to our customers.

1. Engineering Expertise & Collaborative Problem-Solving

At Modelcraft, we don’t just take orders and produce parts—we collaborate with customers to refine designs, optimize manufacturability, and improve overall performance. Our engineering and manufacturing teams work closely with clients to ensure their parts are not only machinable but also cost-effective and high-performing.

Example: A medical device company needed a micro-sized, high-precision component with an extremely tight tolerance. Our team analyzed the design, adjusted machining processes, and ensured a flawless production run.

The Result: A successful partnership that reduced costs and improved product reliability.

2. Mastering Tight Tolerances & Complex Geometries

Many industries, especially aerospace and medical, require parts with micron-level precision. Achieving these tolerances demands advanced equipment, cutting-edge tooling, and skilled machinists who understand how to control every aspect of the machining process.

At Modelcraft, we specialize in small, high-precision components with high-volume automation. Our AS9100D and ISO 9001:2015 certifications ensure that we meet the strictest quality standards.

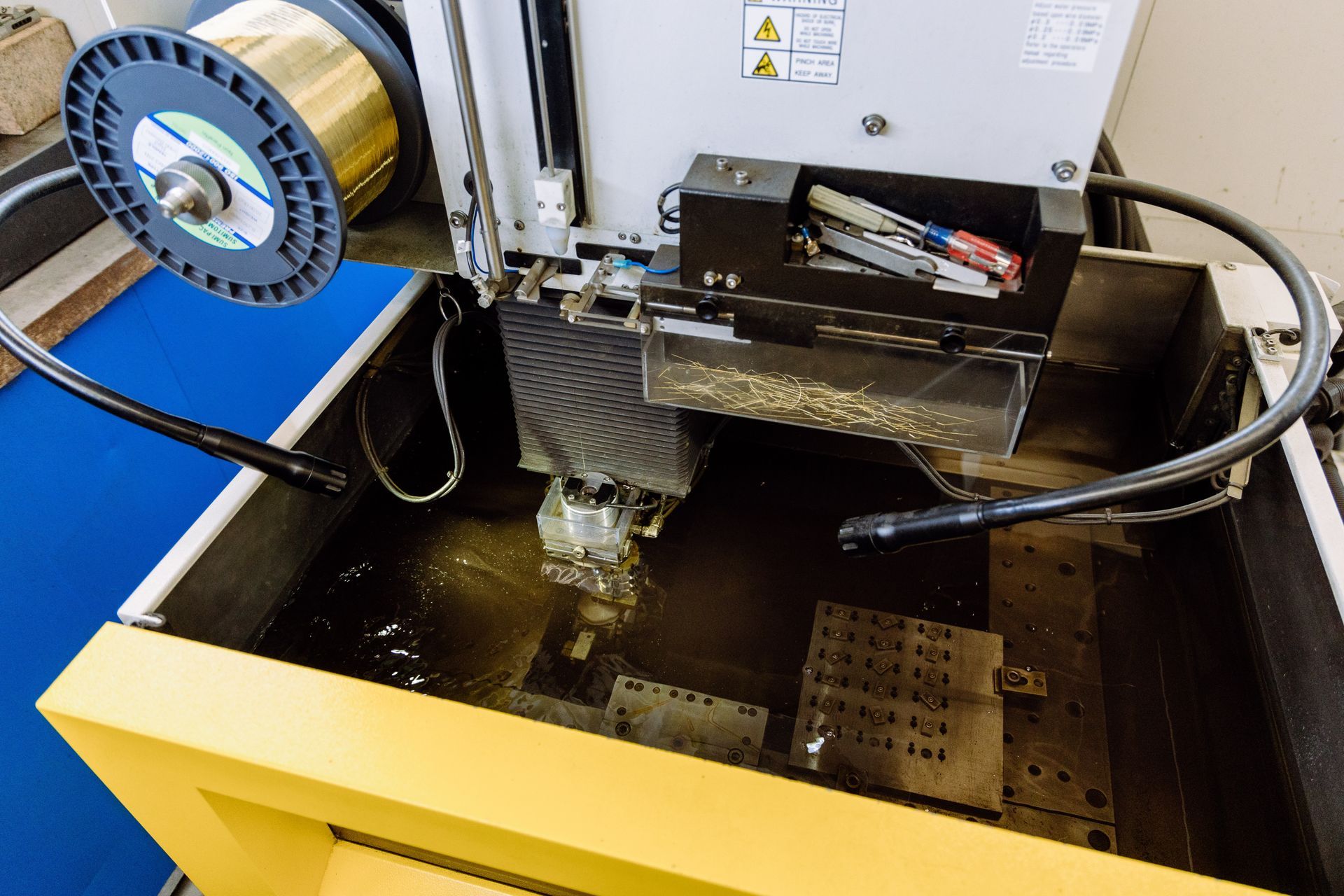

Example: An aerospace client needed an ultra-lightweight, high-strength part with a ±0.0002-inch tolerance. Our 5-axis CNC machining and wire EDM technology allowed us to manufacture the part with extreme accuracy.

The Result: A perfectly machined component that met aerospace compliance standards.

3. Expertise in Advanced Materials & Manufacturing Processes

Not all parts are made from common metals—many industries require specialized materials like titanium, Inconel, and medical-grade stainless steel. These materials present unique challenges, such as tool wear, thermal expansion, and machining complexities.

Modelcraft has invested in the right tools, machining strategies, and quality control processes to handle even the most challenging materials and designs.

Example: A customer in the commercial sector needed a corrosion-resistant component made from an exotic alloy. Our team utilized high-speed machining techniques and precision grinding to manufacture the part without compromising material integrity.

The Result: A durable, high-performance part that exceeded industry expectations.

4. Comprehensive Quality Control & Inspection

High precision means nothing without rigorous inspection and quality assurance. At Modelcraft, every part we manufacture undergoes full inspections, documentation, and quality control checks to ensure compliance with specifications.

- We use state-of-the-art metrology equipment, including:

- CMM (Coordinate Measuring Machines) for high-accuracy dimensional verification

- Optical inspection systems for intricate geometries

- Surface roughness and hardness testing for material consistency

Example: A medical device manufacturer required components with a zero-defect tolerance due to patient safety concerns. Our comprehensive quality control process ensured that each part met stringent FDA and ISO requirements.

The Result: A production run with 100 percent compliance and zero defects, securing the customer’s trust in Modelcraft’s expertise.

Why Choose Modelcraft?

At Modelcraft, we thrive on solving our customers’ toughest challenges. Whether you need precision-machined parts, expert material handling, or comprehensive quality assurance, our team delivers solutions that exceed expectations. Need a manufacturing partner who understands your unique challenges? Contact Modelcraft today.

Recent Articles