Assembly

At Modelcraft Co., our assembly process ensures that each component is meticulously put together to meet the highest quality standards. We specialize in assembling complex parts with precision and efficiency, providing turnkey solutions for various industries. Our experienced team is dedicated to delivering reliable and consistent results for every project.

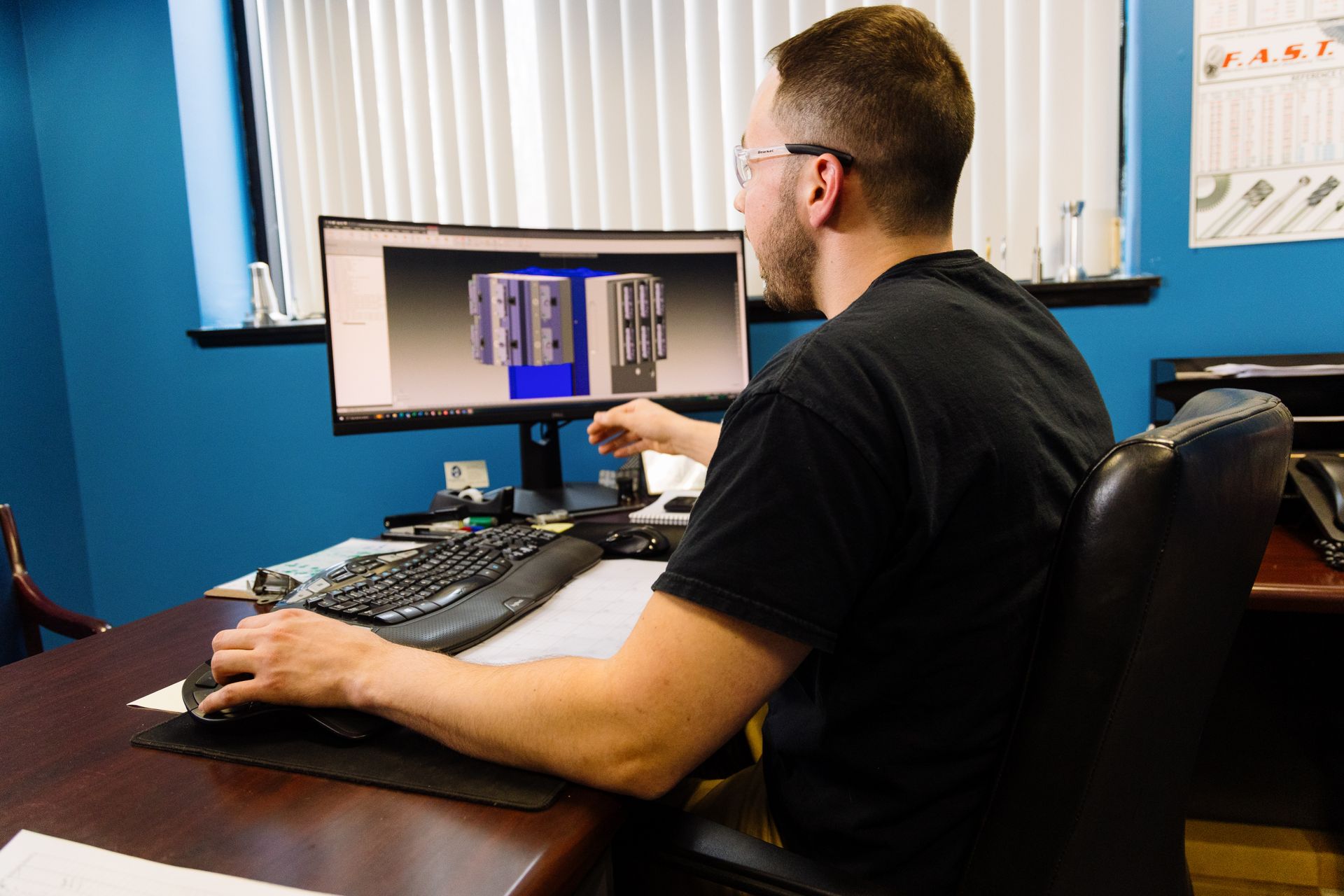

Fixture Engineering

Our fixture engineering services cover design, assembly, and tool tryout, providing comprehensive solutions. Project timelines range from 4 to 16 weeks, depending on complexity. We ensure precision and reliability through integrated quality checks, vision systems, statistical process control, and automated quality checks at every step.

Full CNC Machining

Modelcraft Co.'s full CNC machining services provide high-precision production with advanced technology ensuring accuracy. We engage our customers from quote to delivery, maintaining regular communication for a seamless experience. The process includes assessment, programming, procurement, production, inspection, and shipping, with extra steps for complex parts.

Precision Grinding

At Modelcraft Co., precision grinding ensures unparalleled accuracy and quality for complex components, surpassing the dimensional precision of standard CNC machining. Utilizing state-of-the-art machinery and advanced techniques, we meet stringent tolerances and exact specifications, with project turnaround times ranging from 4 to 16 weeks, depending on complexity.

Prototyping

Modelcraft Co.

specializes in rapid prototyping to bring your designs to life with precision and speed. Our advanced prototyping capabilities allow us to create detailed and accurate models, helping you validate and refine your concepts. With a focus on quality and efficiency, we ensure that your prototypes meet the highest standards before moving to full production.

Supply Chain Management

Our supply chain management services ensure a smooth and efficient flow of materials and products from start to finish. We work closely with trusted suppliers to maintain consistent quality and timely deliveries. By leveraging our robust supply chain network, we can minimize delays and optimize costs, ensuring your projects stay on track.

Tooling

At Modelcraft Co., we provide comprehensive tooling solutions tailored to your specific manufacturing needs. Our expertise in designing and producing high-quality tools ensures that your production processes are efficient and reliable. From custom fixtures to specialized gauges, we deliver tooling that enhances precision and productivity.

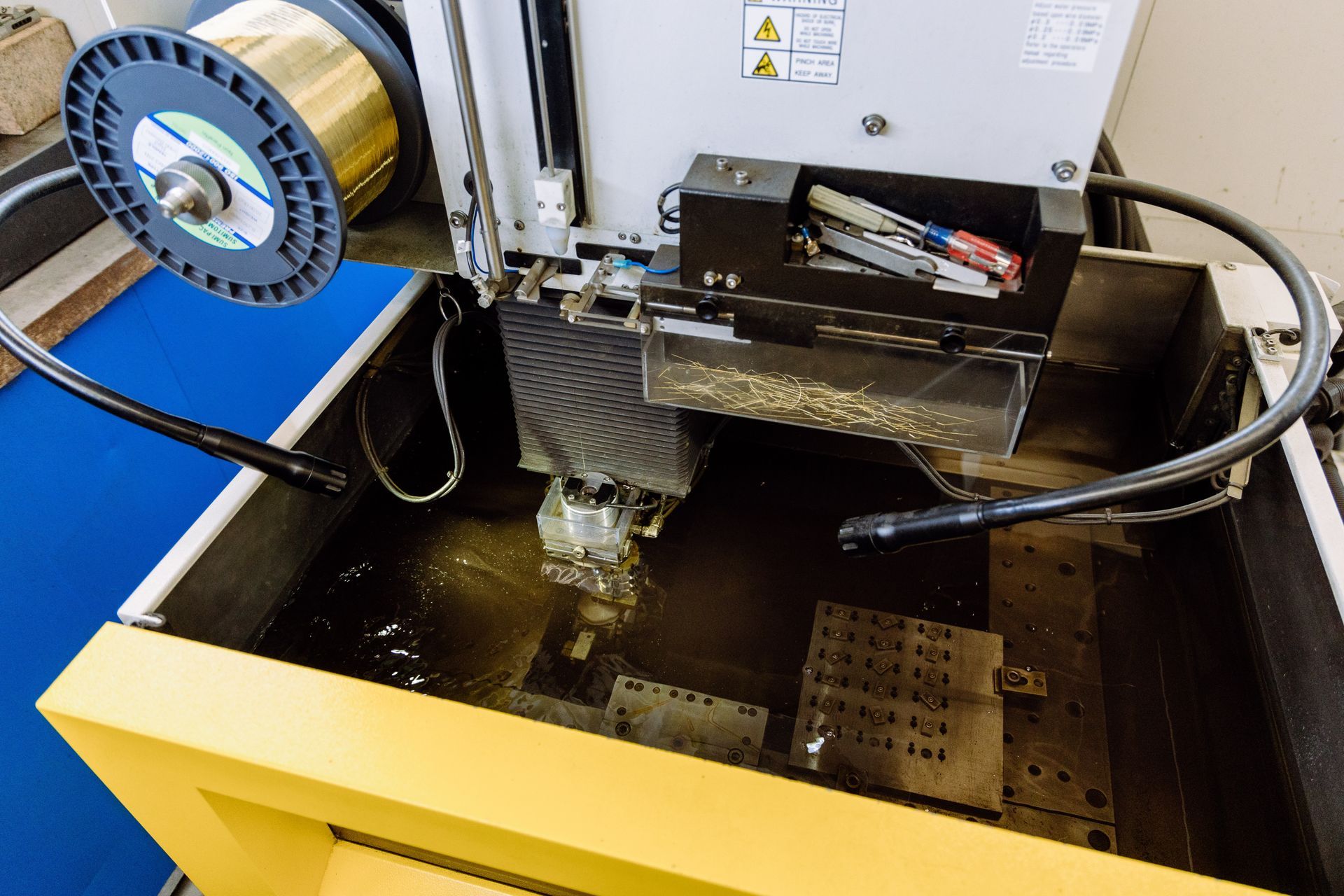

Wire EDM

Our wire EDM services offer unparalleled precision for cutting complex shapes and intricate details. Using advanced wire EDM technology, we can achieve tight tolerances and smooth finishes on a variety of materials. This process is ideal for producing high-precision components required in industries such as aerospace, medical, and automotive.

Common Questions

Here are some common questions we receive about our services. If you have any additional inquiries, feel free to contact us today.

AS9100D

The AS9100D Certification is a globally recognized quality management standard for the aerospace industry. It ensures that Modelcraft meets the rigorous and complex demands of the aerospace sector, providing our clients with the highest quality products and services.

ISO 9001:2015 Certification

The ISO 9001:2015 Certification is an international standard dedicated to Quality Management Systems (QMS). It outlines the framework for improving quality and a vocabulary of understanding for any organization looking to provide products and services that consistently meet the requirements and expectations of customers and other relevant interested parties in the most efficient manner possible.