Precision manufacturing is the foundation of modern industry, enabling the production of highly accurate and reliable components used in aerospace, medical, defense, and commercial applications. As products become more advanced and complex, the need for precision machining continues to grow. But what exactly is precision manufacturing, and why is it so essential?

Defining Precision Manufacturing

Precision manufacturing is a specialized approach to producing components with extremely tight tolerances, high accuracy, and consistency. It involves advanced machining techniques, computer-controlled processes, and strict quality control measures to ensure that each part meets exact specifications.

Unlike traditional manufacturing, where minor variations in parts may be acceptable, precision manufacturing focuses on micron-level accuracy, often within ±0.0001 inches. This level of precision is critical for industries where performance, safety, and reliability depend on perfectly machined components.

Key Characteristics of Precision Manufacturing

1. Tight Tolerances

Precision manufacturing achieves exceptionally small tolerances, ensuring that parts fit together flawlessly in high-performance applications.

2. Advanced Machining Technology

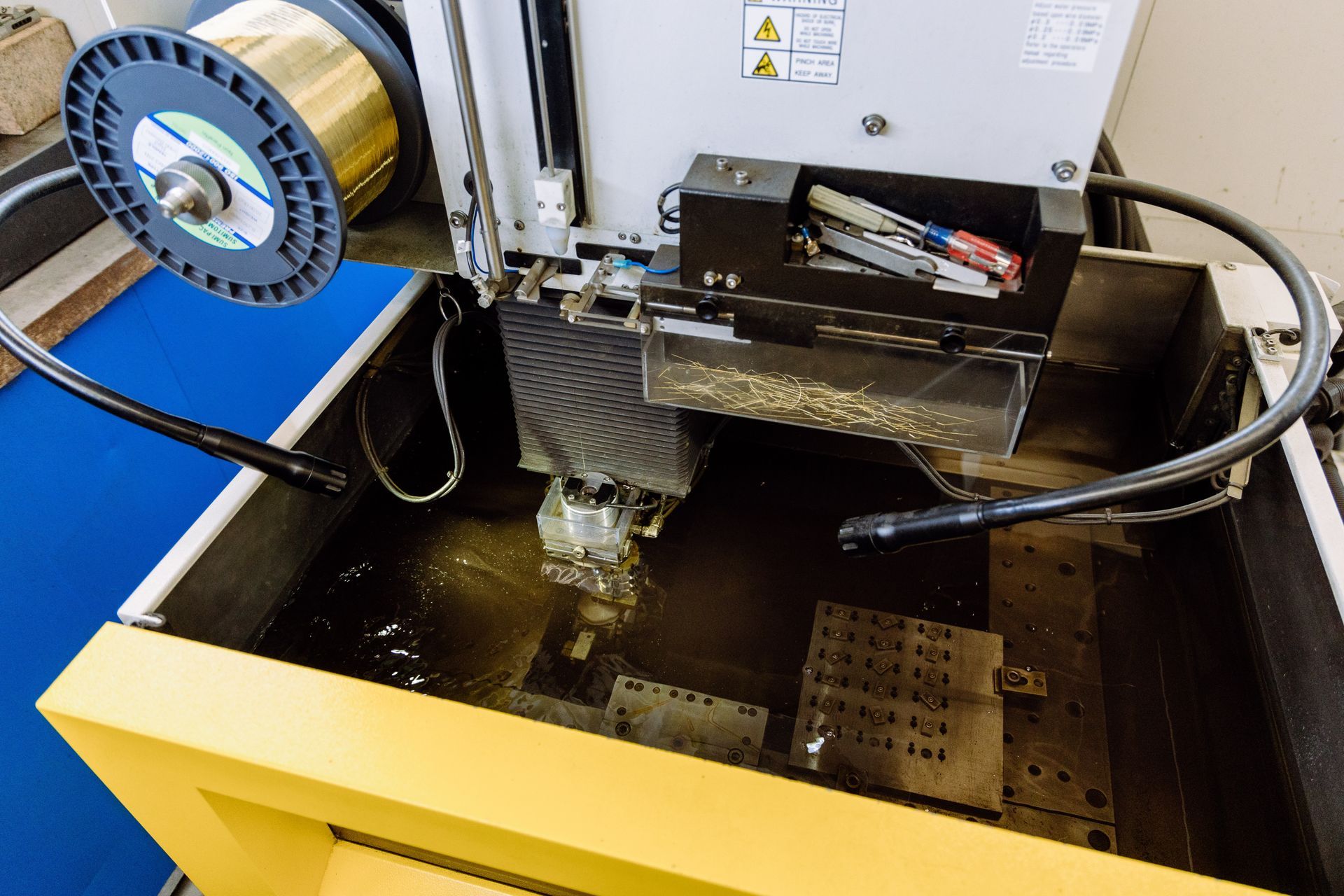

It utilizes CNC machining, Wire EDM, laser cutting, and other high-precision techniques to produce complex geometries with repeatable accuracy.

3. High-Quality Materials

Materials like titanium, Inconel, stainless steel, and aluminum are commonly used due to their strength and durability.

4. Strict Quality Control

Precision manufacturing requires AS9100D and ISO 9001:2015 certification, along with advanced inspection equipment, to ensure that every part meets exact specifications.

5. Repeatability & Consistency

Industries like aerospace and medical require identical parts to be produced in large quantities with no deviation, making repeatability a core feature of precision manufacturing.

Precision Manufacturing Processes

Various machining and finishing techniques contribute to the precision manufacturing process, including:

- CNC Machining – Computer-controlled milling and turning for high-precision parts.

- Wire EDM – Electrical Discharge Machining for intricate cuts and fine details.

- Grinding – Producing ultra-smooth finishes with extreme accuracy.

- Laser Cutting – High-speed cutting with minimal material waste.

- Inspection & Metrology – CMM (Coordinate Measuring Machines) and digital inspection tools ensure parts meet exacting standards.

Industries That Rely on Precision Manufacturing

Precision manufacturing plays a crucial role in industries where accuracy, durability, and reliability are non-negotiable. Some key sectors include:

- Aerospace – Aircraft components, turbine blades, and structural assemblies.

- Medical – Surgical instruments, orthopedic implants, and micro-machined parts.

- Defense – High-performance weapon systems and electronic enclosures.

- Automotive – High-performance engine components and precision tooling.

- Electronics – Circuit board components and semiconductor parts.

Why Precision Manufacturing Matters

1. Performance & Reliability

High-precision components ensure optimal performance and longevity, reducing failure rates in mission-critical applications.

2. Safety & Compliance

Industries like aerospace and medical must adhere to strict safety regulations, making precision manufacturing essential for meeting industry standards.

3. Innovation & Customization

Precision manufacturing enables the production of custom, high-performance parts for cutting-edge technologies and next-generation products.

Your Trusted Precision Manufacturing Partner

With 55+ years of experience, Modelcraft Co. specializes in high-precision manufacturing for aerospace, medical, and commercial industries. Our AS9100D and ISO 9001:2015-certified facility is equipped with advanced CNC machining, Wire EDM, and rigorous quality control to ensure unmatched accuracy, consistency, and reliability. Whether you need complex geometries, tight tolerances, or high-performance materials, our expertise ensures superior results. Get in touch with us today to discuss how our precision manufacturing solutions can meet your needs.

Recent Articles

Get a Quote

For more information or to request a quote, call us at (860) 283-0257 or complete the form.

Contact Us

We will get back to you as soon as possible.

Please try again later.

What Happens After I Send My Message?

Our team will review your information.

A staff member will contact you as soon as possible.

Once your requirements are understood we'll get back to you promptly with a quote.

Contact Information

Our Services

Quick Links

Business Hours

- Monday

- -

- Tuesday

- -

- Wednesday

- -

- Thursday

- -

- Friday

- -

- Saturday

- Closed

- Sunday

- Closed

Accepted Payments