At Modelcraft Co., we recognize the importance of strong leadership and technical expertise in delivering high-quality precision-machined parts. Dave Hill, our Vice President of Quality & Engineering, brings over 25 years of aerospace industry experience to our team, playing a key role in maintaining the highest standards of quality and efficiency.

Role at Modelcraft

As VP of Quality and Engineering, Dave oversees both departments to ensure precision, efficiency, and continuous improvement in manufacturing processes. His focus is on placing the right people in the right roles, optimizing workflows, and maintaining strict quality control standards to consistently deliver reliable parts to our customers.

A Notable Accomplishment

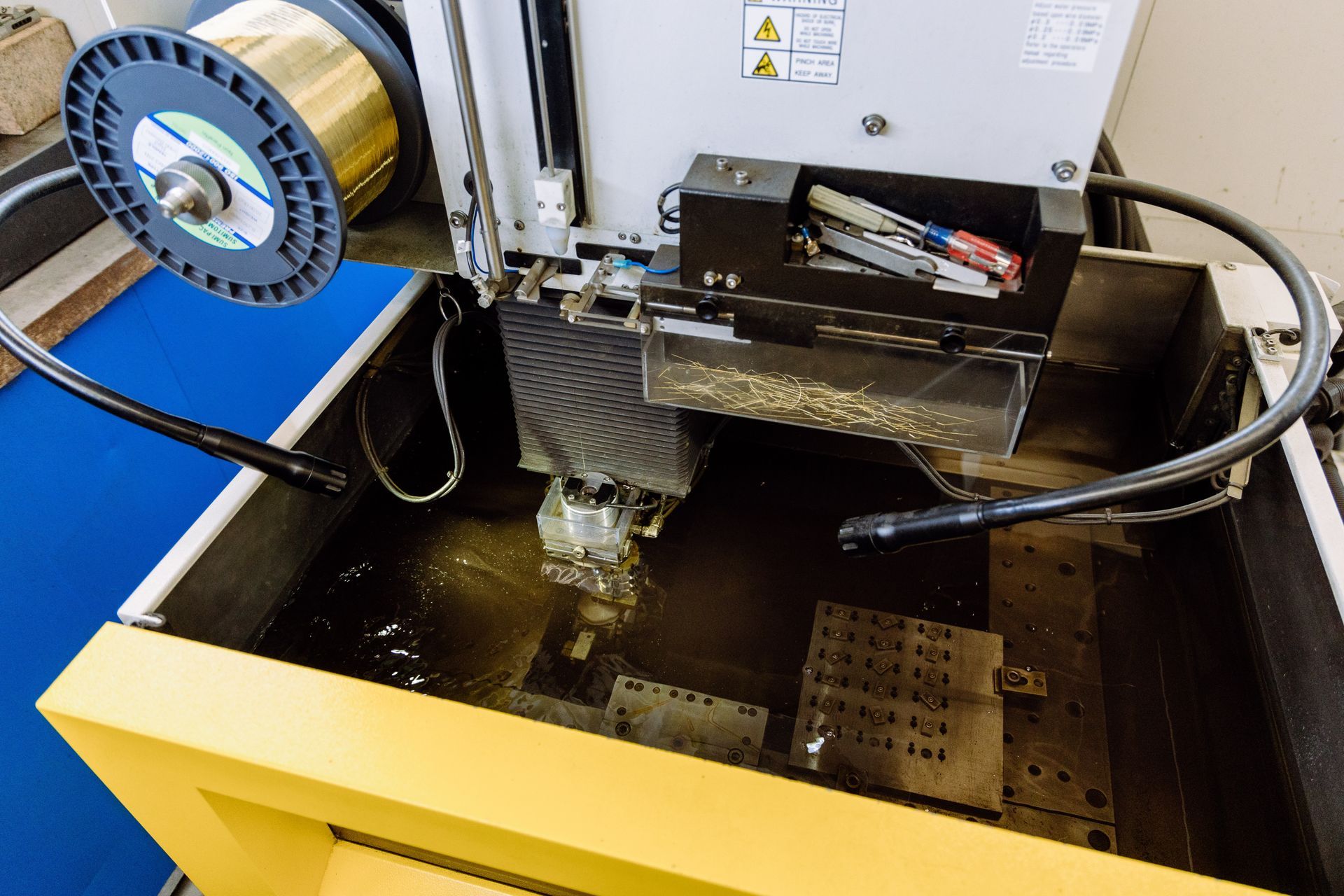

One of Dave’s most significant achievements at Modelcraft was assisting a defense industry customer with a highly complex part that required extremely tight tolerances and precise edge finishes. Through innovative process development and problem-solving, he led the effort to successfully manufacture and deliver the part, demonstrating Modelcraft’s ability to meet the most challenging requirements.

Commitment to Excellence

Dave is hardworking, supportive, and detail-oriented, with a strong commitment to identifying opportunities for improvement and growth. He stays current with industry advancements through technical articles and podcasts, particularly in CNC machining and aerospace manufacturing. His continuous learning approach directly contributes to Modelcraft’s success.

Personal and Professional Motivation

Dave values honesty, self-motivation, hard work, and problem-solving—principles that guide both his professional and personal life. He finds motivation in tackling new challenges, driving company success, and providing for his family. His primary goal at Modelcraft is to maximize efficiency and quality while fostering a culture of continuous improvement.

Beyond the Workplace

Outside of work, Dave enjoys working out and spending time with his family. He takes great pride in watching his children succeed, considering it one of his most significant personal achievements.

Modelcraft Co. is fortunate to have Dave’s leadership and expertise as we continue to advance our capabilities and maintain our reputation for precision and quality. His dedication to process improvement, quality assurance, and team development makes a lasting impact on both our operations and the customers we serve.

Recent Articles

Get a Quote

For more information or to request a quote, call us at (860) 283-0257 or complete the form.

Contact Us

We will get back to you as soon as possible.

Please try again later.

What Happens After I Send My Message?

Our team will review your information.

A staff member will contact you as soon as possible.

Once your requirements are understood we'll get back to you promptly with a quote.

Contact Information

Our Services

Quick Links

Business Hours

- Monday

- -

- Tuesday

- -

- Wednesday

- -

- Thursday

- -

- Friday

- -

- Saturday

- Closed

- Sunday

- Closed

Accepted Payments