CNC machining is one of the most vital processes in modern manufacturing. From aerospace components to life-saving medical devices, CNC (Computer Numerical Control) machines make it possible to produce precise, high-quality parts at scale. But if you're new to the world of machining, you might be wondering—is CNC machining hard?

At Modelcraft Co., we’ve spent decades mastering the art and science of CNC machining, and the truth is: it’s not necessarily hard—it’s just highly specialized. Let’s break down what makes CNC machining both a rewarding and challenging discipline.

What Makes CNC Machining Complex?

CNC machining requires a combination of technical knowledge, hands-on experience, and problem-solving skills. It involves:

Understanding materials (like metals, plastics, and composites)

Reading technical drawings and blueprints

Programming machines using G-code or CAM software

Setting up and operating complex equipment

Measuring and inspecting finished parts to tight tolerances

That might sound like a lot, and it is—but with the right training and the right tools, it becomes manageable and efficient.

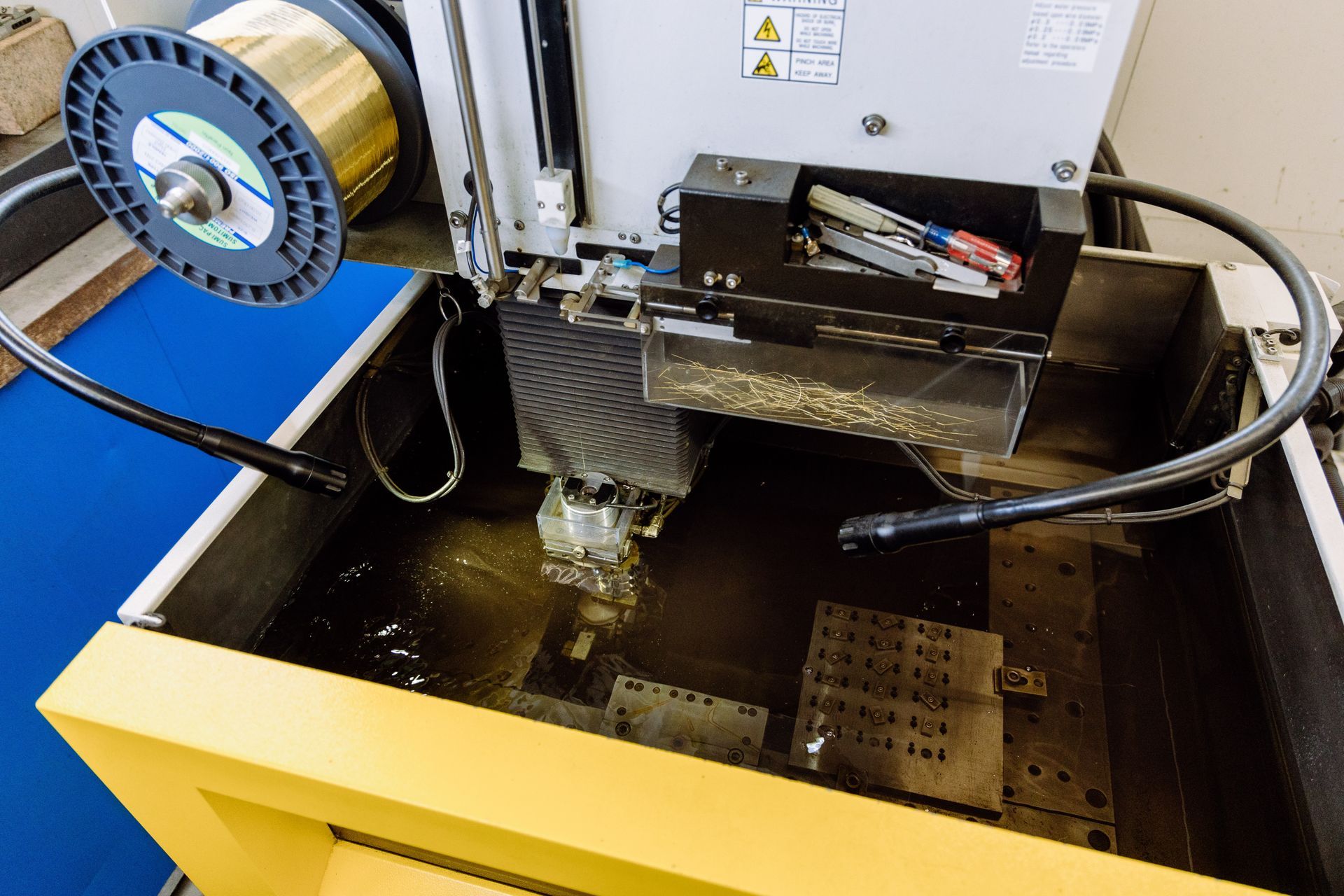

The Role of Technology

One of the biggest advantages of CNC machining is that the heavy lifting is done by the machine—once it’s properly programmed. This removes much of the manual guesswork required in conventional machining. At Modelcraft Co., our team uses advanced CNC systems integrated with cutting-edge software to produce intricate parts with minimal variability.

While the machines do the machining, operators and programmers are responsible for ensuring everything is dialed in correctly. That's where skill, attention to detail, and experience come in.

Is It Hard to Learn CNC Machining?

Like any technical skill, CNC machining comes with a learning curve. However, thanks to modern training programs, online courses, and on-the-job mentorship, it’s more accessible than ever. For those with an interest in technology, mechanics, and precision, CNC machining can be incredibly fulfilling.

At Modelcraft Co., many of our team members started with zero CNC experience and developed into expert machinists through hands-on learning and continuous improvement. Our commitment to training and innovation ensures that we stay at the cutting edge—and help others grow with us.

Why Experience Still Matters

While CNC machines are powerful, they still require skilled operators and engineers to program, monitor, and maintain them. Precision machining often calls for creative problem-solving, especially when dealing with complex parts, exotic materials, or high-tolerance specs.

That’s why companies across the medical, aerospace, and commercial sectors trust Modelcraft Co.—our experienced team knows how to tackle tough challenges and deliver high-quality results.

So, Is CNC Machining Hard?

In short: it can be challenging, but it’s far from impossible—especially with the right tools, training, and mindset. CNC machining is a high-skill, high-reward field that blends engineering, craftsmanship, and technology.

At Modelcraft Co., we believe in making precision manufacturing accessible and efficient. Whether you're exploring a career in machining or looking for a trusted partner for your next manufacturing project, we're here to help.

Ready to Work With CNC Experts?

If your business needs high-precision machined parts or you're curious about how CNC can improve your manufacturing process, reach out to the team at Modelcraft Co.. With nearly 60 years of experience and a passion for solving complex manufacturing challenges, we’re your go-to CNC partner.

Contact us today at [email protected] or call (860) 791-3425 to get started.

Recent Articles

Get a Quote

For more information or to request a quote, call us at (860) 283-0257 or complete the form.

Contact Us

We will get back to you as soon as possible.

Please try again later.

What Happens After I Send My Message?

Our team will review your information.

A staff member will contact you as soon as possible.

Once your requirements are understood we'll get back to you promptly with a quote.

Contact Information

Our Services

Quick Links

Business Hours

- Monday

- -

- Tuesday

- -

- Wednesday

- -

- Thursday

- -

- Friday

- -

- Saturday

- Closed

- Sunday

- Closed

Accepted Payments