What Is CNC Machining & How Does It Work?

CNC machining, short for Computer Numerical Control machining, is a modern manufacturing process that uses computer software to control machine tools. These tools—such as mills, lathes, grinders, and wire EDM machines—shape raw materials into precise parts and components. It’s a core technology at Modelcraft Co., enabling us to deliver high-precision, high-tolerance parts for the medical, aerospace, and commercial industries.

How Does CNC Machining Work?

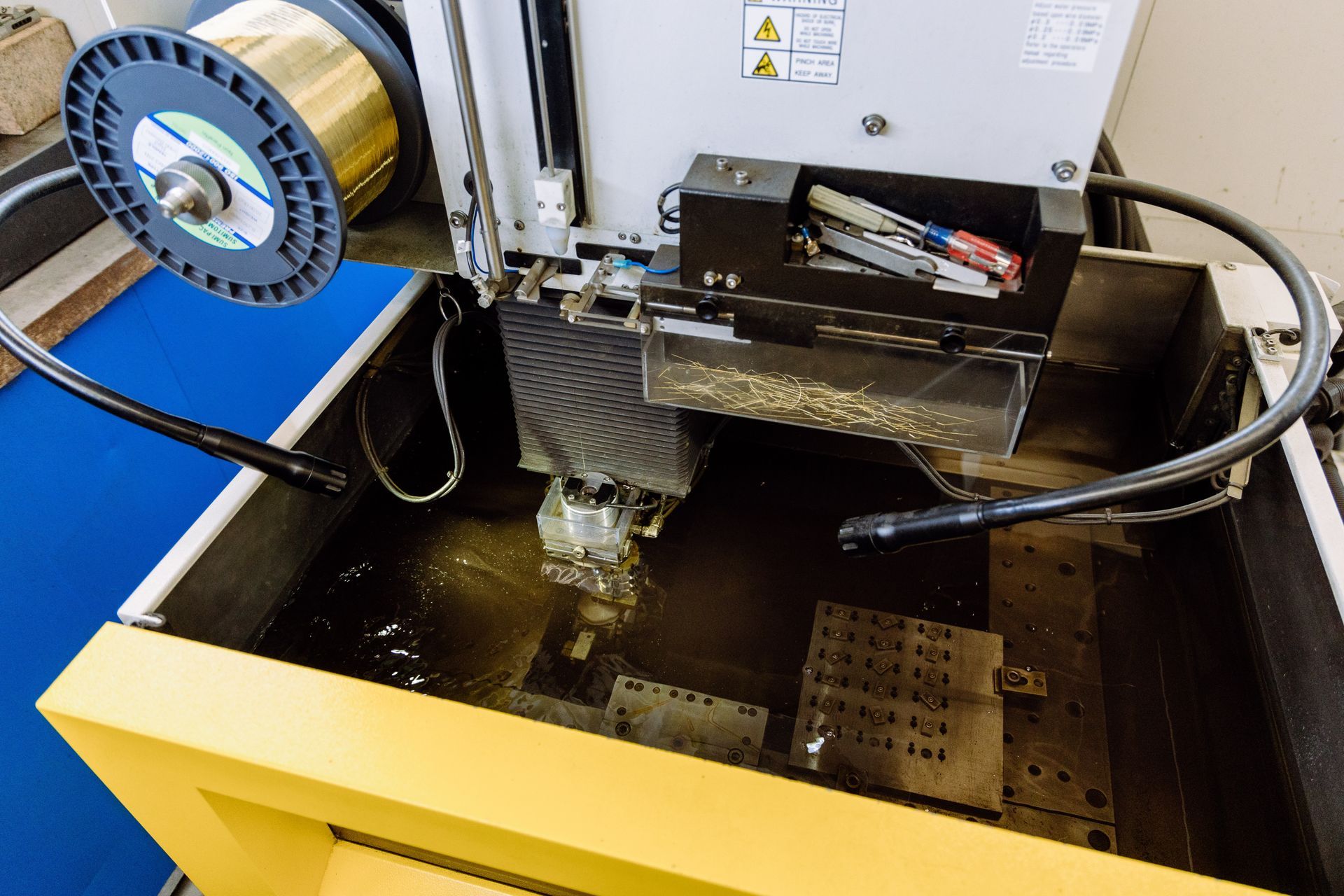

The process begins with a digital design, usually a CAD (Computer-Aided Design) model created by engineers. That file is then converted into a CNC program using CAM (Computer-Aided Manufacturing) software, which tells the machine exactly how to move, cut, or shape the material. Once the CNC machine is programmed, it runs with minimal human intervention, making the process highly accurate and repeatable. Whether it's

milling, turning,

grinding, or

wire EDM, each machine follows programmed instructions down to the smallest movement—often within microns.

Why CNC Machining Matters

At Modelcraft Co., CNC machining allows us to consistently produce complex, tight-tolerance parts—many of which are small components used in mission-critical applications. Because the process is automated and tightly controlled, the risk of human error is significantly reduced, and production speed and efficiency increase. We also complement our machining with full inspections and quality control at every step. Our AS9100D and ISO 9001:2015 certifications ensure that every part we produce meets the highest industry standards.

Built for the Toughest Challenges

CNC machining is not just about cutting metal—it’s about solving problems. Our customers come to us with tough challenges: intricate geometries, difficult materials, or the need for high-volume precision. With nearly 60 years of experience, Modelcraft Co. delivers turnkey manufacturing solutions that help customers succeed.

Need Parts That Don’t Flake Under Pressure? Let’s Talk.

When precision isn’t optional, you need a machining partner who gets it right the first time—and every time after that. At Modelcraft Co., we’ve been pushing the limits of what CNC machining can do for nearly 60 years. From tight tolerances to tight deadlines, we’re built to handle your toughest challenges. Contact Modelcraft Co. today to request a quote or talk through your next project—we’re ready when you are.

Recent Articles