Why It’s Critical to Prototype with Your Production Supplier: Lower Costs and Minimize Risks

When developing a new product, one of the most crucial steps is prototyping. However, partnering with your production supplier for this phase can provide substantial benefits over working with a separate prototyping firm. At Modelcraft Co., we’ve seen firsthand how prototyping with your production supplier can streamline the process, ultimately lowering costs and reducing risks. Here’s why it’s a smart choice.

1. Seamless Transition to Production

When you work with your production supplier on prototyping, you can ensure that the prototype aligns directly with production capabilities from the start. This approach enables a seamless transition to full-scale production, reducing the need for costly adjustments or reconfigurations. Because your supplier understands the limitations and opportunities of their equipment, they can guide design modifications that make the transition from prototype to production smoother and more cost-effective.

2. Realistic Cost Estimations

Prototyping with a production supplier provides a more accurate picture of production costs early in the process. Production suppliers can help you select cost-effective materials and processes that fit both your prototyping needs and your budget. Since production suppliers are familiar with scaling up, they can offer insights on how the prototype will impact long-term production costs, helping you avoid surprises down the road.

3. Reduced Risk of Design Flaws

Designs can often look great on paper but encounter unforeseen issues when moving to production. When your production supplier is involved from the beginning, they can offer valuable input based on experience, helping to identify potential design flaws early. By prototyping with the people who will ultimately manufacture your product, you can address and fix these issues before they become costly production problems, saving you time and resources.

4. Faster Iterations and Turnaround

Time is often of the essence when developing new products, especially in competitive industries. By working with your production supplier, you’ll benefit from a streamlined process where design modifications can be implemented and tested more quickly. This reduces the back-and-forth that can occur when working with separate prototyping firms and accelerates your time to market.

5. Improved Quality Control

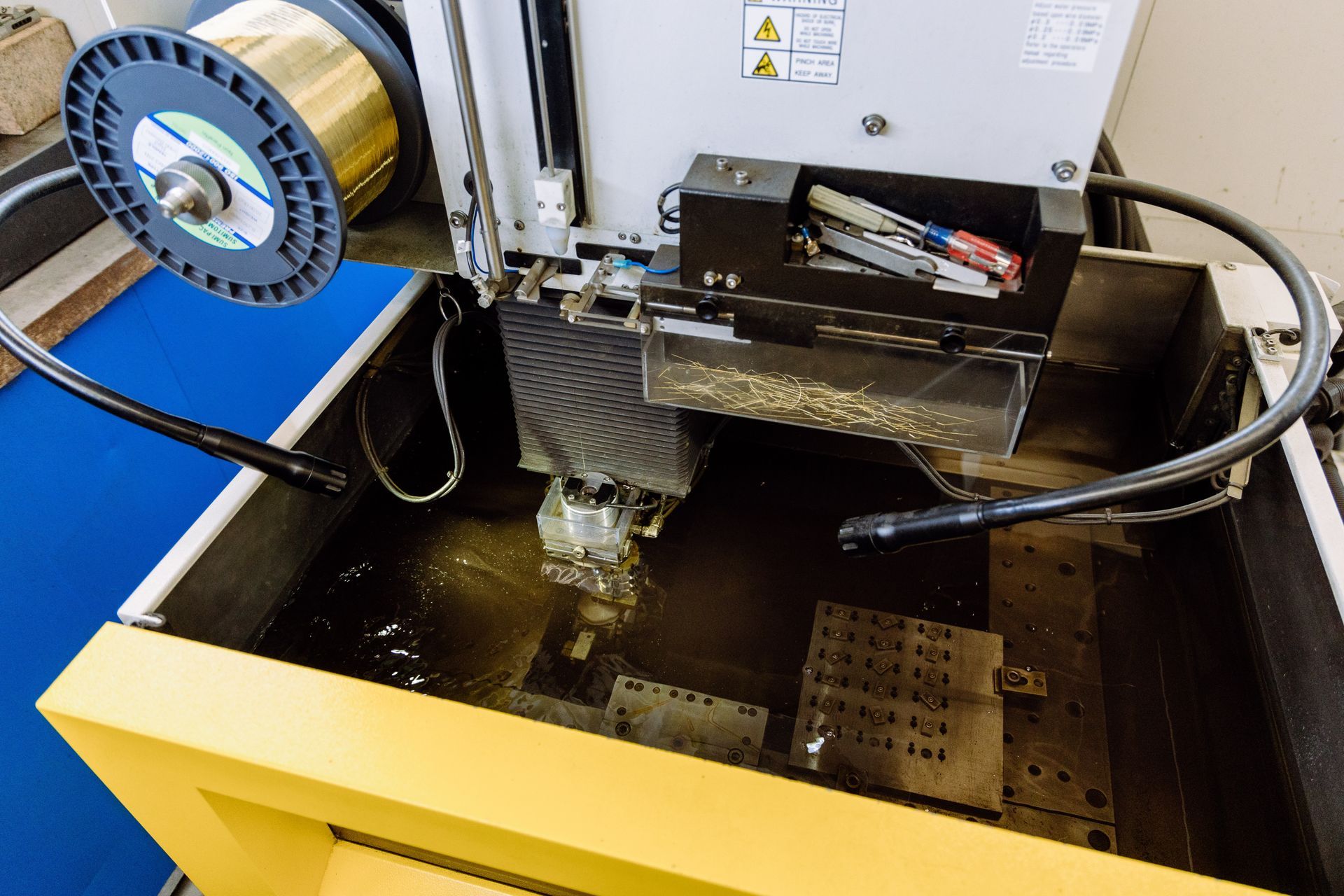

Your production supplier is responsible for the final product's quality and precision. When they’re involved from the prototyping phase, they have a vested interest in ensuring that the prototype meets high standards. They’re also more likely to have advanced quality control processes in place, giving you peace of mind that every prototype iteration is made with precision and accuracy.

Prototype With Us

Prototyping with your production supplier isn’t just a practical choice; it’s a strategic one that can significantly reduce costs and minimize risks. By integrating the prototyping and production phases, you’ll experience smoother transitions, better cost control, reduced risk, and faster iterations — all essential factors for successful product development. At Modelcraft Co., we offer a full range of prototyping and production services to help you bring your product to life efficiently and cost-effectively. If you’re ready to discuss your next project, reach out to our team and let’s build something exceptional together.

Recent Articles