Case Study:

In the highly competitive field of medical manufacturing, Siemens Health has relied on trusted partners to meet its stringent standards for sourcing metal materials and products. For the past eight years, Siemens Health has found such a partner in Modelcraft Co. Jeff, the Global Commodity Manager of Metal Parts at Siemens Health, shares his insights into this enduring partnership and the value Modelcraft Co. brings to the table.

A Longstanding Relationship with Continuous Growth

When Jeff joined Siemens Health eight years ago, Modelcraft Co. was already a trusted supplier. Since then, the partnership has only grown stronger. "We’ve ramped up the volume quite a bit with them," Jeff notes, reflecting the confidence Siemens Health has in Modelcraft Co.'s capabilities.

Why Siemens Health Chooses Modelcraft Co.

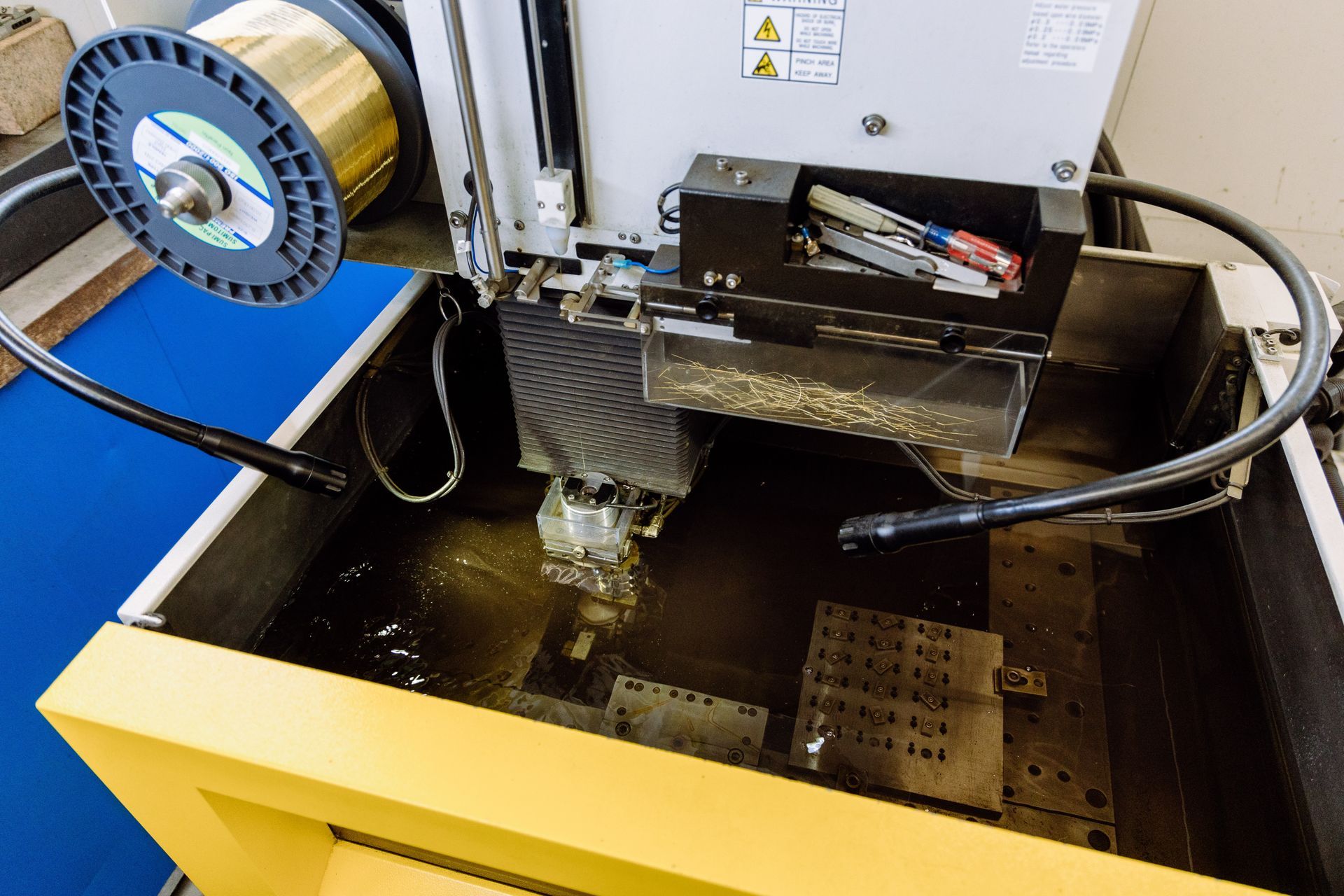

The decision to continue and expand this partnership is based on several key factors, with cost competitiveness and a commitment to continuous improvement being at the forefront. "Modelcraft Co. is not just about meeting today’s needs—they're willing to invest in new machinery and processes to ensure that we’re always moving forward," Jeff explains. This proactive approach to innovation has made Modelcraft Co. an invaluable partner to Siemens Health.

Challenges and Overcoming Obstacles

While the journey hasn’t always been smooth, Jeff appreciates Modelcraft Co.'s dedication to making things right. "There were some bumps along the way, but the right intent is always there. They’re committed to improving and that’s crucial for us."

Solving Problems Through Continued Development

One of the most significant problems that Modelcraft Co. helps Siemens Health solve is the need for continuous improvement in the manufacturing process. "They’re always looking for ways to reinvent the machining process to increase efficiency," Jeff highlights. This focus on constant improvement aligns perfectly with Siemens Health’s objectives, making Modelcraft Co. a strategic partner.

What Siemens Health Values Most About Modelcraft Co.

At the heart of this successful partnership is the high level of communication and trust that Modelcraft Co. provides. "Knowing that you can call them up and talk to the right person the first time is invaluable," says Jeff. He also emphasizes the honesty and integrity that define Modelcraft Co.’s approach. "We can take their word for it, which is something we really value."

Describing Modelcraft Co. to a Colleague

When asked how he would describe Modelcraft Co. to a colleague, Jeff is clear: "They’re a competent machine shop that focuses on small to medium size parts in a cost-competitive manner." This concise endorsement captures the essence of what makes Modelcraft Co. a reliable and trusted partner.

A Partner You Can Trust

Trust and integrity are the cornerstones of Modelcraft Co.'s relationship with Siemens Health. "Modelcraft has a strong sense of understanding in the parts and what it takes to make them well at a competitive price," Jeff concludes. This trust, coupled with a commitment to continuous improvement and effective communication, ensures that Siemens Health can rely on Modelcraft Co. to meet their complex manufacturing needs.

Explore The Modelcraft Advantage

At Modelcraft Co., we are committed to helping our clients achieve their goals through innovative solutions, high-quality manufacturing, and a partnership built on trust. Whether you’re looking to improve efficiency, reduce costs, or ensure the highest standards of quality, our team is ready to support your success. Contact us today to learn more about how we can help your business thrive.

Recent Articles

Get a Quote

For more information or to request a quote, call us at (860) 283-0257 or complete the form.

Contact Us

We will get back to you as soon as possible.

Please try again later.

What Happens After I Send My Message?

Our team will review your information.

A staff member will contact you as soon as possible.

Once your requirements are understood we'll get back to you promptly with a quote.

Contact Information

Our Services

Quick Links

Business Hours

- Monday

- -

- Tuesday

- -

- Wednesday

- -

- Thursday

- -

- Friday

- -

- Saturday

- Closed

- Sunday

- Closed

Accepted Payments