Case Study:

At Modelcraft Co., we pride ourselves on building long-lasting relationships with our clients by consistently delivering exceptional quality and reliability. One such partnership that truly stands out is our 40-year relationship with Hoffman Engineering, a leader in the industry. Ron Curtin, the Production Planning Manager at Hoffman Engineering, has worked closely with Modelcraft Co. for over 35 years, managing everything from purchasing and planning to inventory and shipping.

A History of Trust and Excellence

Hoffman Engineering has been working with Modelcraft Co. for more than four decades, a partnership rooted in trust, consistent quality, and a shared commitment to precision. Ron Curtin recalls, "We've been using Modelcraft Co. for as long as I've been here, over 35 years. Their quality is a significant reason we continue to choose them. We inspect everything that comes in based on rigorous standards, and their products consistently meet our specifications."

Solving Complex Challenges with Advanced Capabilities

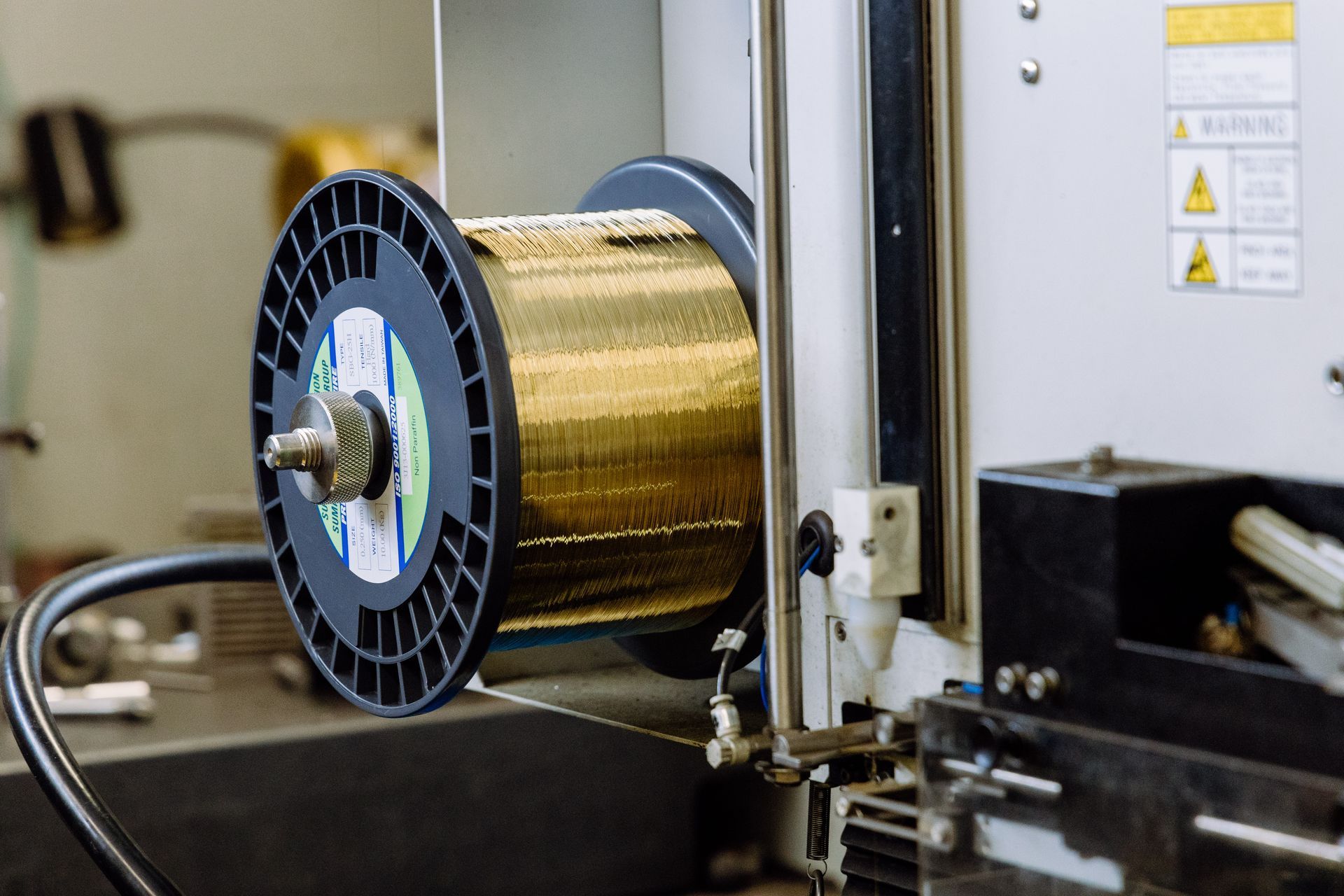

One of the major reasons Hoffman Engineering continues to partner with Modelcraft Co. is our ability to handle complex manufacturing challenges. "Some of our parts are very difficult to produce with tight tolerances, and Modelcraft Co. has the advanced machinery to make it happen. The fact that they can work with both plastic and metal under one roof is incredibly convenient for us," Curtin explains.

Reliability in Delivery and Quality

In the manufacturing industry, consistency and reliability are critical, and Modelcraft Co. excels in both. Hoffman Engineering monitors their suppliers annually, evaluating on-time delivery and quality. "Modelcraft Co. is always at the highest level of our suppliers when it comes to quality. They might not be the cheapest, but they are always reliable," says Curtin. "We wouldn't continue working with them if they weren't up to par. They’re very good with their projected timelines."

A Relationship Built on Attention to Detail and Dedication

Ron Curtin also highlights Modelcraft Co.'s meticulous approach to meeting client needs. "They're dedicated to meeting your needs, detail-oriented, and they don't assume anything—they always ask for clarity to get the product right," he notes. This commitment to precision and customer satisfaction is a cornerstone of our business philosophy at Modelcraft Co.

Local Convenience with a Personal Touch

One of the added benefits of working with Modelcraft Co. is our proximity to Hoffman Engineering. "It's also convenient that they’re local. If you need something in a hurry, they’ll come right down and deliver it," Curtin mentions. Our close location allows us to provide quick and efficient service when needed, strengthening the partnership further.

A Valued Partnership

As Curtin reflects on his years working with Modelcraft Co., he emphasizes the professionalism and dedication of our team. "Rich and the team are great to work with. They’re professional, detail-oriented, and always looking to improve the business. They have a great crew, and I’ve been working with my account manager for years. It’s a pleasure to work with them."

For over 40 years, Modelcraft Co. has been a trusted partner to Hoffman Engineering, providing high-quality, precision-machined parts that meet their rigorous standards. Our shared commitment to excellence and reliability has fostered a relationship built on trust, respect, and mutual success.

At Modelcraft Co., we are committed to enabling our customers' success by solving their hardest manufacturing challenges with precision and dedication. Whether you need small, high-precision components or turnkey solutions, our experienced team is here to deliver the highest quality products on time, every time. Contact us today to learn how we can support your manufacturing needs.

Recent Articles

Get a Quote

For more information or to request a quote, call us at (860) 283-0257 or complete the form.

Contact Us

We will get back to you as soon as possible.

Please try again later.

What Happens After I Send My Message?

Our team will review your information.

A staff member will contact you as soon as possible.

Once your requirements are understood we'll get back to you promptly with a quote.

Contact Information

Our Services

Quick Links

Business Hours

- Monday

- -

- Tuesday

- -

- Wednesday

- -

- Thursday

- -

- Friday

- -

- Saturday

- Closed

- Sunday

- Closed

Accepted Payments